Accessories

Load cells

Ground anchors can be installed with a monitoring facility. Where a structure is sensitive to changes in load or ground movement use can be made of this facility to monitor the behaviour throughout its design life. The number of anchors to be monitored and the measurement interval must be specified.

Protection CAP for TTR-E anchorages

In an aggressive environment, the anchor head must be immediately protected, both with temporary and with permanent anchors. The protection inside the heat provides an efficient connection with the free length protection, in order to protect the small reinforcement section below and through the bearing plate. The grouting of the back part of the anchorage can be carried out from the central hole, which also allows air to be released. The back filling of the anchorage, together with the containment offered by the under plate protection, represent the correct application to guarantee the necessary protection. If no reloading and stressing controls are required, resins, mixtures and other sealing products can be inserted into the head cap. On the contrary, if reloading and stressing controls are required, the protection of the external part of the head, including the cap and its content, must be removable. It must be possible to reload the cap with the anticorrosion product.

Underplate Protection

The purpose of the under plate protection is to provide an effective connection/protection between the sheath of the free length and the anchorage.

Its function consists in protecting the small section of tendon under the bearing plate and to guarantee the continuity of the sheath.

A painted or grouted plastic or metal rigid sleeve is sealed or welded to the anchor head. It is sealed to the free length sheath or duct and filled with corrosion protection compound, cement or resin.

Its function consists in protecting the small section of tendon under the bearing plate and to guarantee the continuity of the sheath.

A painted or grouted plastic or metal rigid sleeve is sealed or welded to the anchor head. It is sealed to the free length sheath or duct and filled with corrosion protection compound, cement or resin.

Spherical supports

DD-SF spherical supports are recommended for the installation of temporary and permanent inclined ground anchors, offering the installer:

- Correction of boring angles,

- No use of welded structures to guarantee square anchoring,

- Easy installation,

- Easy fixing to the bulkhead

Packer

The packer is used to restrain the primary grouting and allow it to be carried out guaranteeing a greater expansion of the bulb. The properly inflated packer allows to obstruct the drilling hole, thus avoiding grout cement or groundwater leaks.

Grouting tubes

All the tubes used are 16x20 mm. In special cases, where the insertion of all the tubes is difficult due to dimensions, 11.5x14 mm o 13x16 mm tubes are used for vent only. Tubes come in 5 colours to identify their applications; for their identification a base operating instruction and the relating specifications for special applications are given.

Tubo valvolato 15/21 per iniezioni I.R.

Tubo valvolato 27/34 per iniezioni I.R.S.

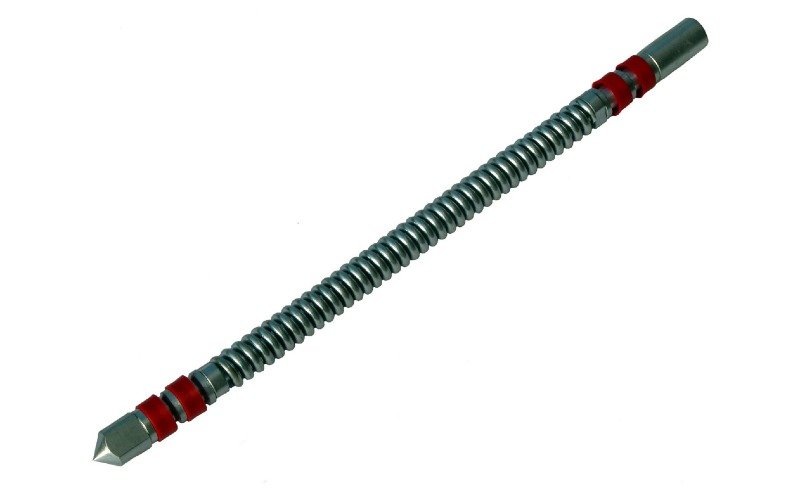

Double piston for I.R.S. grouting

The double piston for I.R.S. groutings type XG27-600is produced with a highly resistant spring, allowing flexibility; it compensates for the natural deviations of the valvate tube and guarantees selective grouting (I.R.S.) of the manchette valves up to a max. pressure of 46 bar. I.R.S. groutings must only be carried out by using the XG27-600 double piston.

Internal spacers

DD-DS internal spacers are designed to allow the anchor in the foundation to guarantee the sinusoid effect of the strands inside the corrugated sheaths, as well as the separation of the strands and tubes necessary for the grouting and vent activity. Internal spacers are only installed in the foundation. Spacers are mounted manually according to the anchor assembly specifications, and in any case with a max. pitch of 1.5 m. They are fixed with metal or tape straps to allow a correct flow of the grouting flow with no obstructions.

External spacers

We offer centering systems of two types: DD-EF and DD-ED. They are supplied separately and must be installed on the permanent anchor before its installation on site, as agreed with the Client's Technical Representative. On the Client's request, anchors are supplied with centralizers that allow the anchor centering in the hole and a minimum of 10 mm grout cover to the borehole wall. Spacers/centralizers do not impede the grout flow and are manufactured from corrosion resistant materials.

Centralizer

END CAP

All permanent anchors have an end cap connected to the corrugated protection sheath. The plastic end cap is fixed to the corrugated sheath with a suitable tape to secure it and ease the insertion into the drilling hole.